Introduction

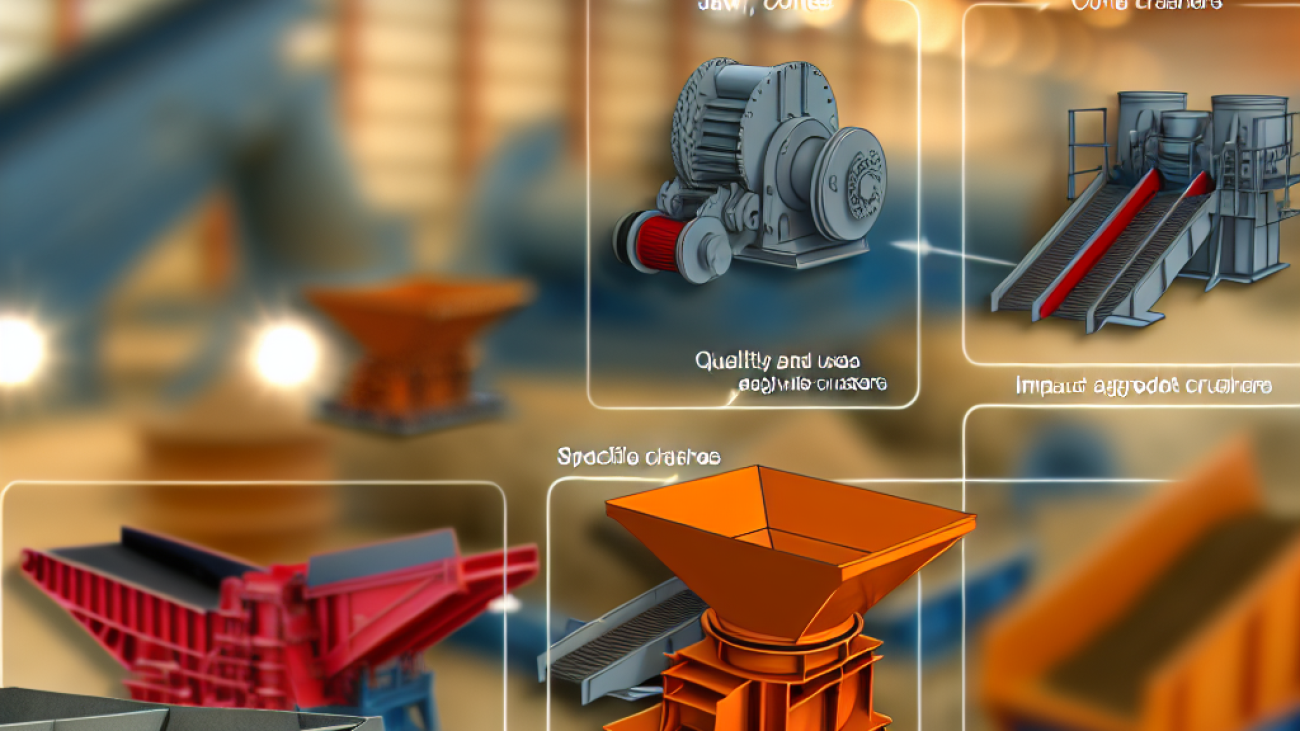

Aggregates are essential materials in construction, and their processing requires efficient crushing equipment. Crushers are machines designed to reduce the size of large rocks and stones into smaller, more manageable pieces. Different types of crushers are available, each with unique features and applications. In this article, we will explore the main types of aggregate crushers and their uses.

Jaw Crushers

Jaw crushers are one of the most common types of aggregate crushers. They work by using a *jaw* to compress and crush materials. The jaw consists of two plates: a fixed plate and a movable plate. As the movable plate swings back and forth, it crushes the material against the fixed plate.

Jaw crushers are ideal for primary crushing, meaning they handle the largest raw materials. They are widely used in quarries, mining, and construction projects. Their simplicity, reliability, and ability to handle large volumes make them a popular choice for initial size reduction.

Cone Crushers

Cone crushers are another popular type of aggregate crusher. They consist of a cone-shaped head that rotates within a bowl. The material is fed into the top and crushed as it passes between the cone and the bowl.

Cone crushers are often used for secondary or tertiary crushing, as they excel at producing smaller, finer particles. They are particularly effective in processing hard and abrasive materials. These crushers are widely used in mining, road construction, and industrial applications where precise particle size is required.

Impact Crushers

Impact crushers work by using a rotor to propel materials against a breaker plate or apron. The material is repeatedly struck and shattered until it reaches the desired size.

Impact crushers are versatile and are commonly used for both primary and secondary crushing. They are especially effective for producing high-quality aggregates for concrete and asphalt. Their ability to handle a wide variety of materials makes them a valuable asset in many crushing operations.

Conclusion

Aggregate crushers are crucial for processing raw materials into usable sizes. Jaw crushers, cone crushers, and impact crushers each have unique designs and applications. By understanding their differences and uses, industries can choose the most appropriate equipment for their needs, ensuring efficient and effective aggregate production.